What is a linear feeder and how does it work?

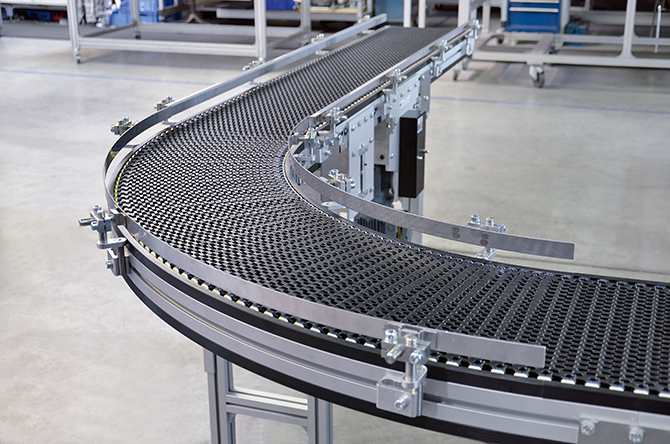

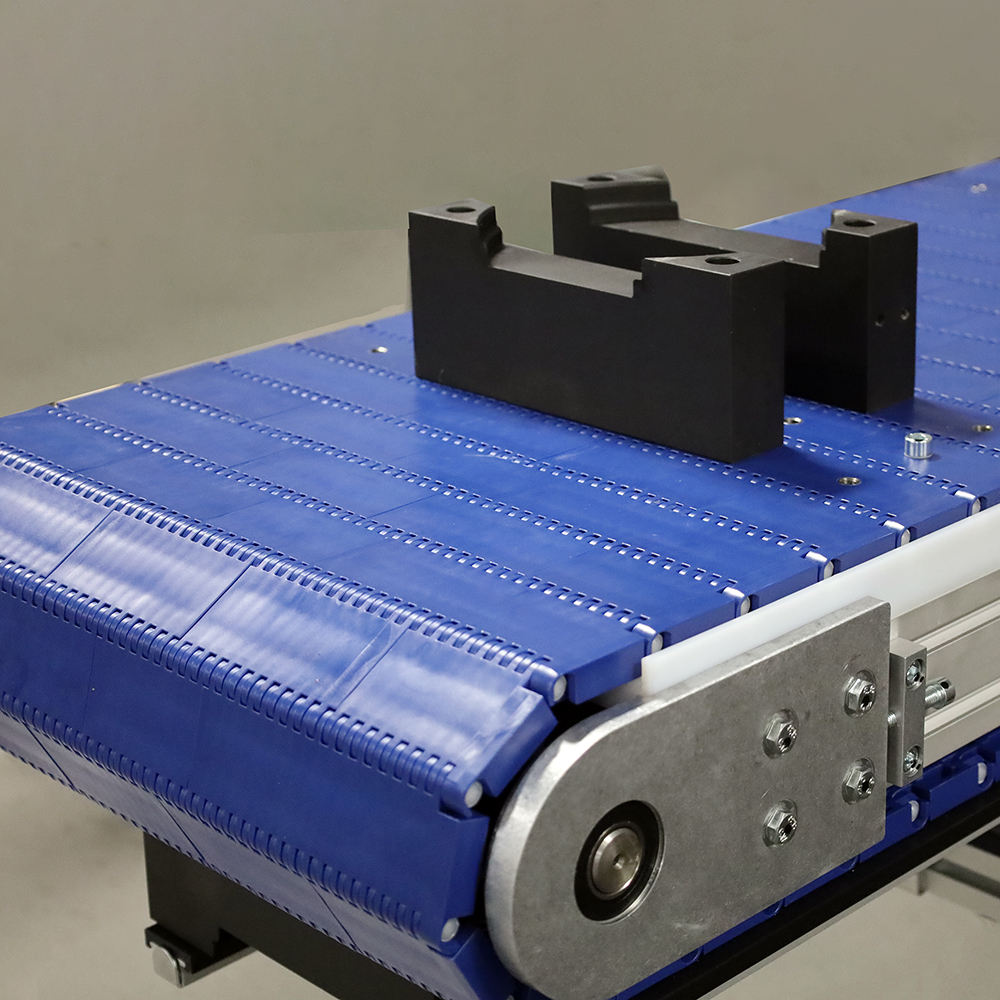

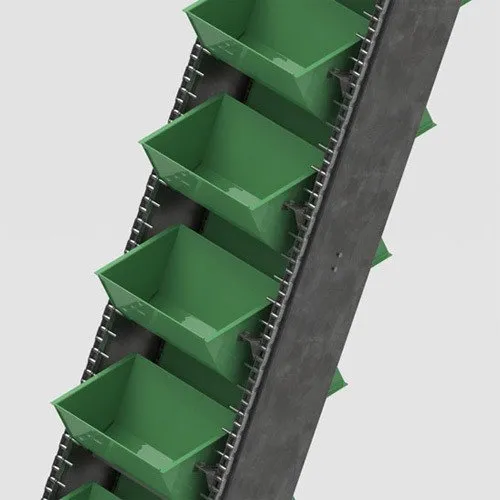

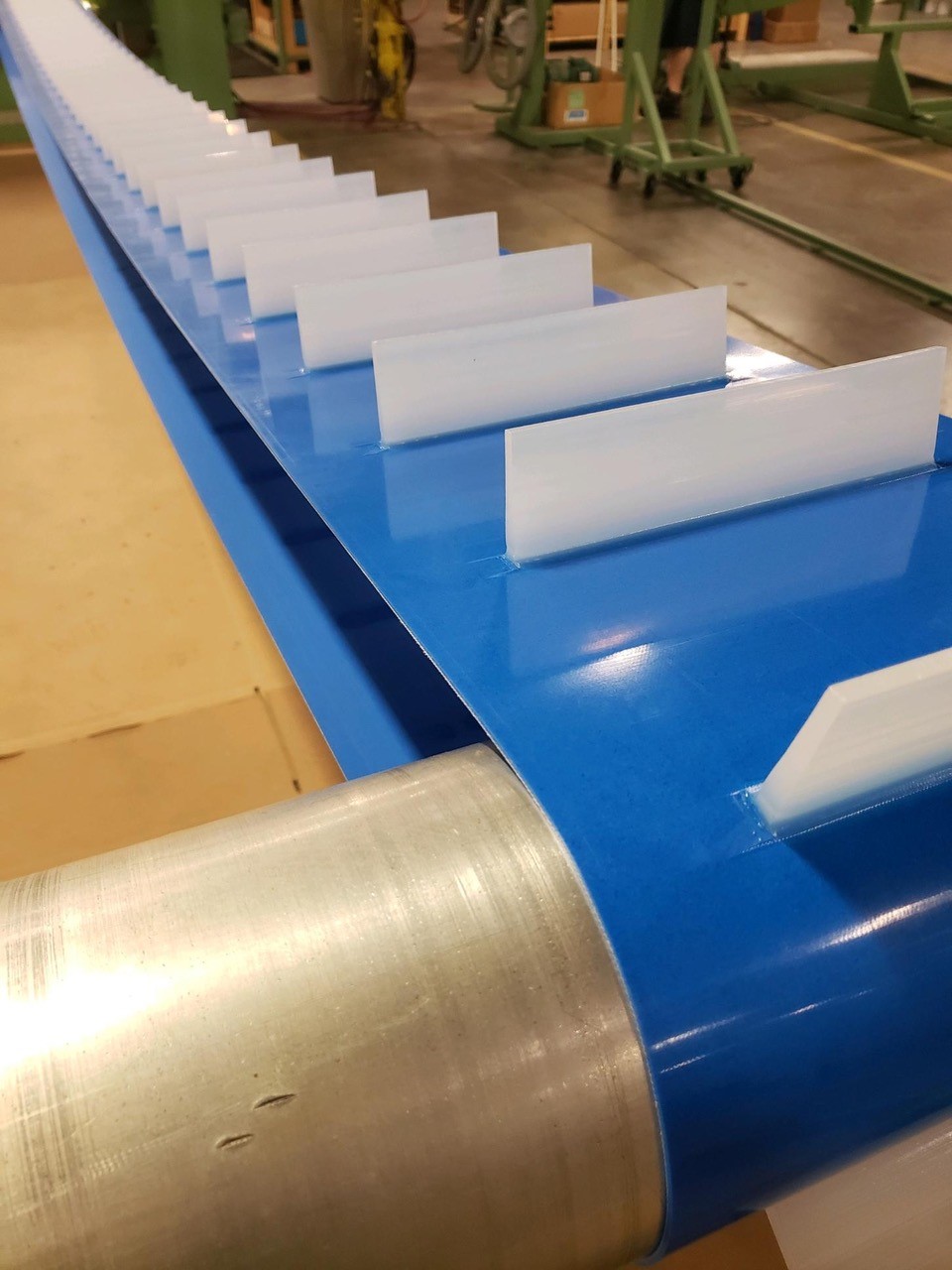

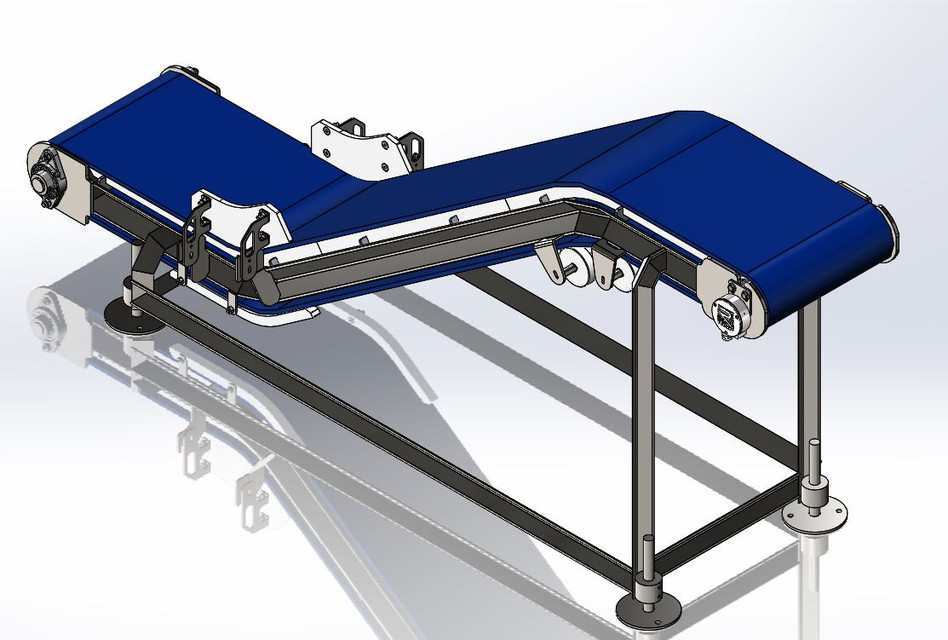

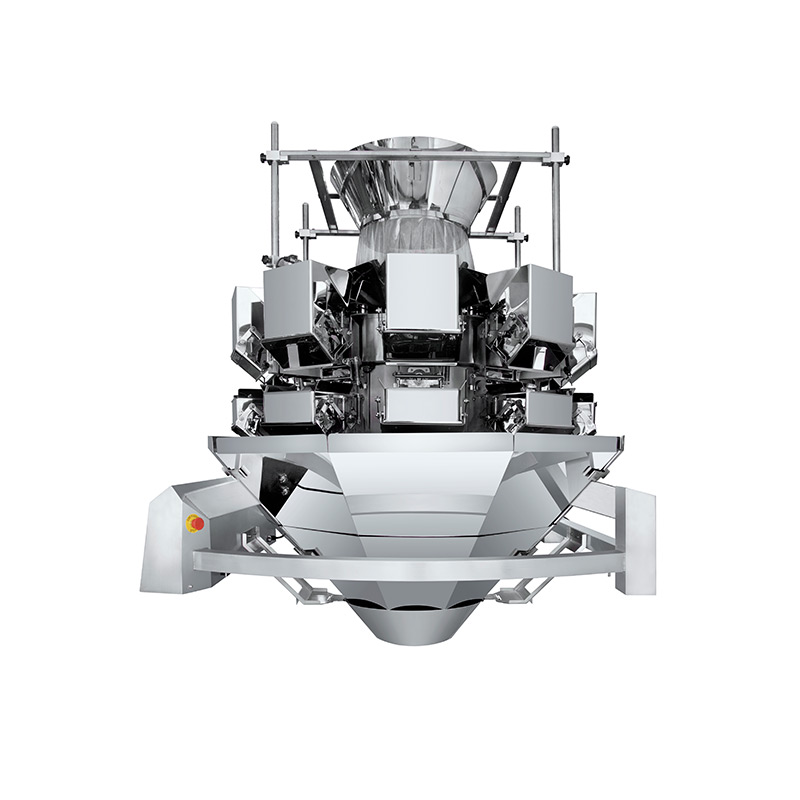

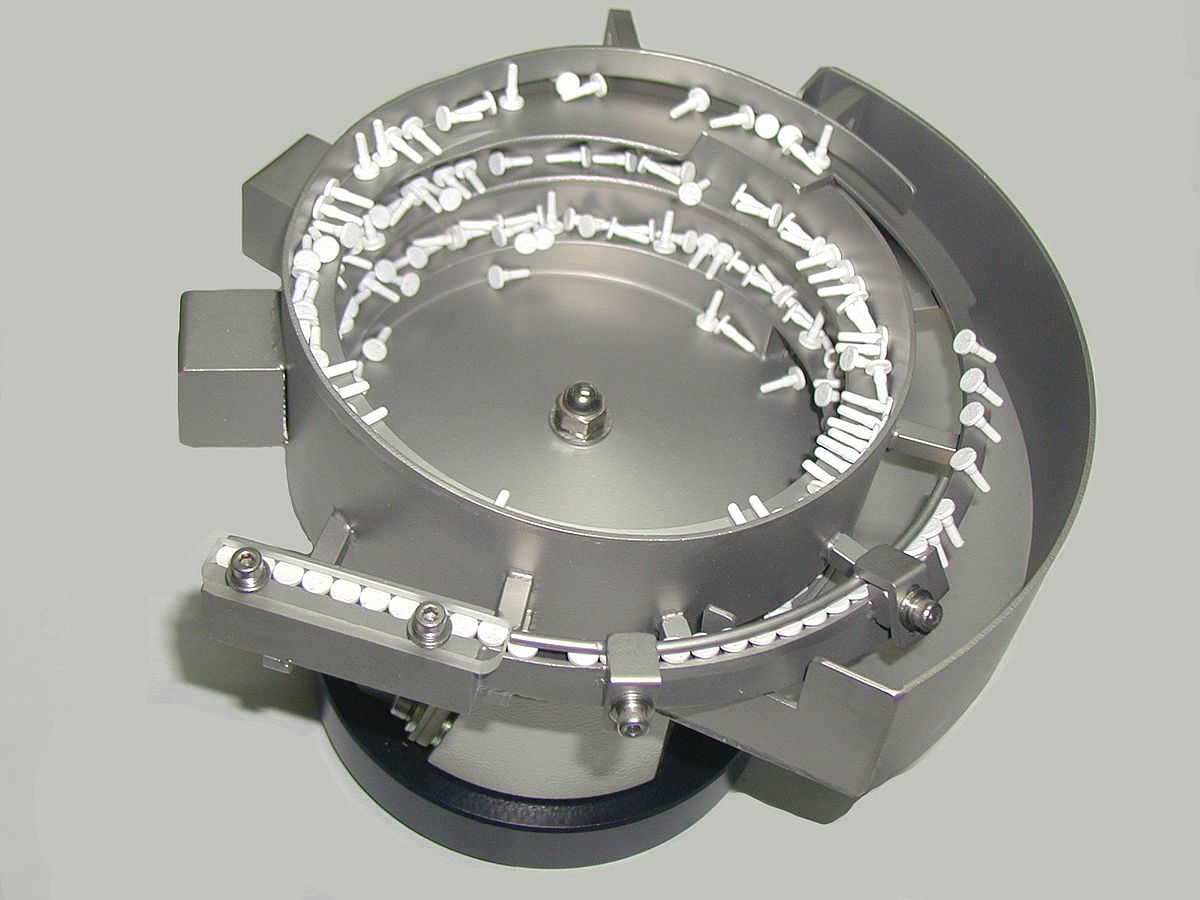

A linear feeder is a type of conveyor system that uses vibrations to move parts or components in a straight line. It consists of a vibrating base a bowl and a controller that regulates the speed and frequency of the vibrations. The linear feeder works by vibrating the bowl which causes the parts or components to move along the track in a controlled and consistent manner.

What types of industries use linear feeders?

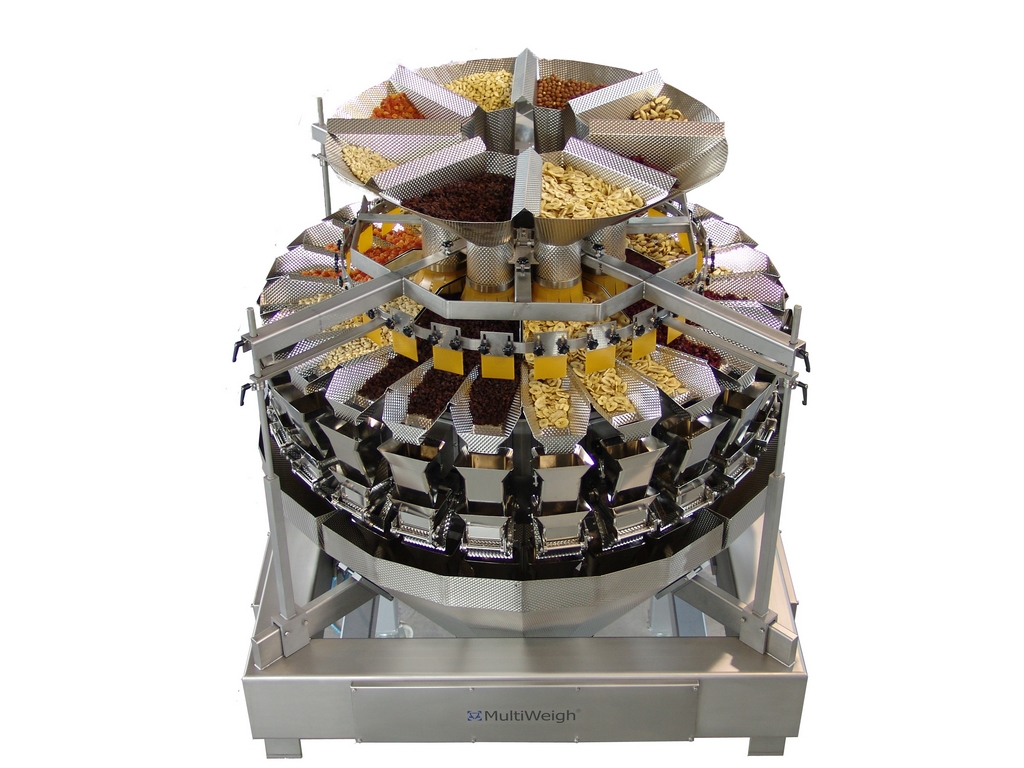

Linear feeders are commonly used in industries that require automated assembly or handling of small parts or components. These include industries such as automotive electronics pharmaceuticals food and beverage and packaging.

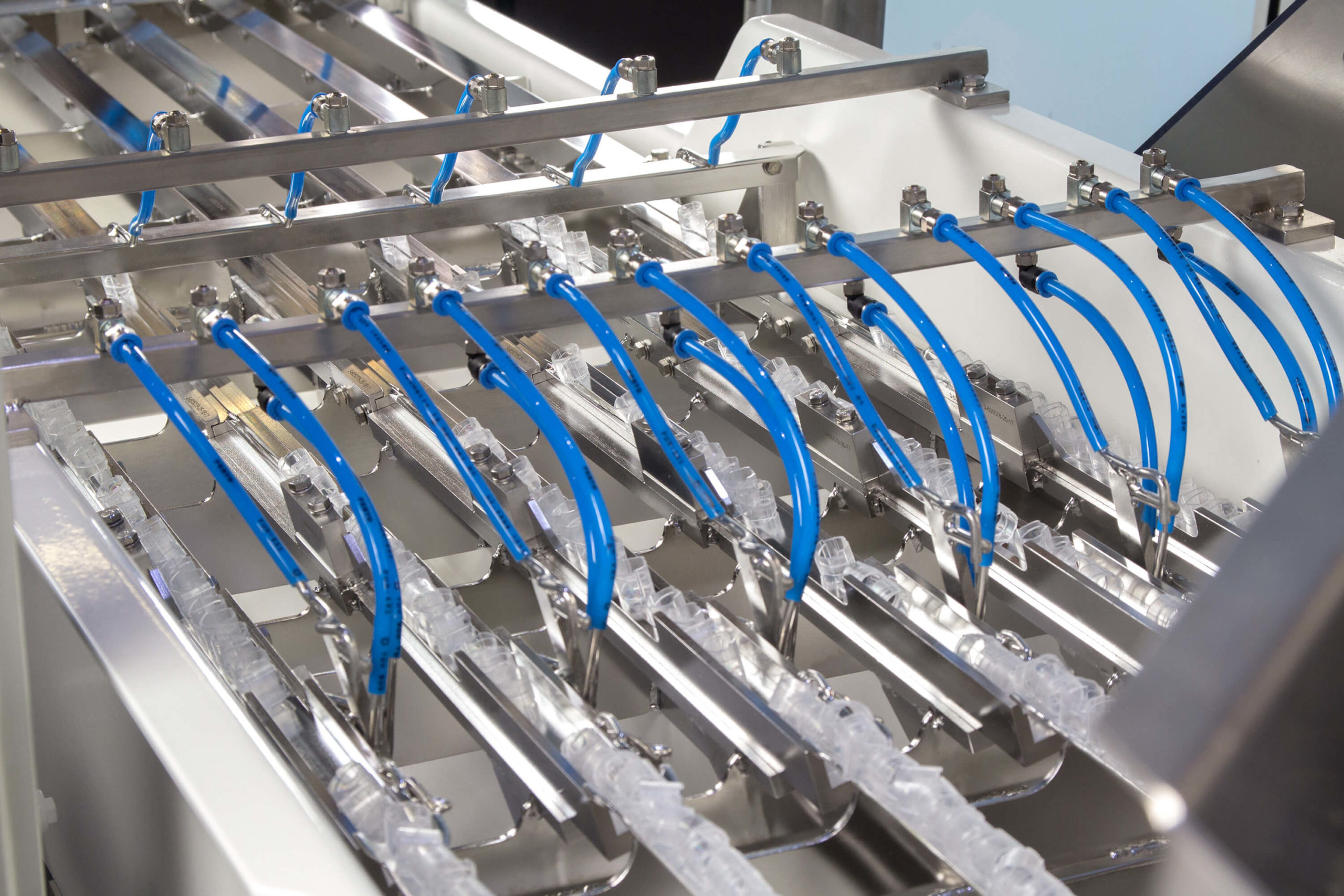

What materials are used to make linear feeders?

Linear feeders can be made from a variety of materials depending on the application and the environment in which they will be used. Common materials include stainless steel aluminum and plastic.

What are the benefits of using a linear feeder in manufacturing?

Using a linear feeder in manufacturing can increase efficiency and productivity by automating the handling and assembly of small parts or components. It can also improve accuracy and reduce errors as well as minimize labor costs and reduce the risk of worker injury.

How does Parthax ensure the quality of their linear feeders?

Parthax is committed to delivering high-quality linear feeders to their customers. They use only the best materials and employ advanced manufacturing techniques to ensure the reliability and durability of their products. They also perform rigorous testing and quality control checks at every stage of production to ensure that each linear feeder meets their strict standards.